Siemens NX MCD: SimpleRobotic Arm Modelling

Siemens NX MCD: Simple Robotic Arm Modelling

In this module, you will model a simple robotic arm mechanism using Siemens NX.

What You Need

Software

- Siemens NX version 1872 or newer (pre-installed on the lab PC)

Files

CAD files of the examples used in this module can be found here.

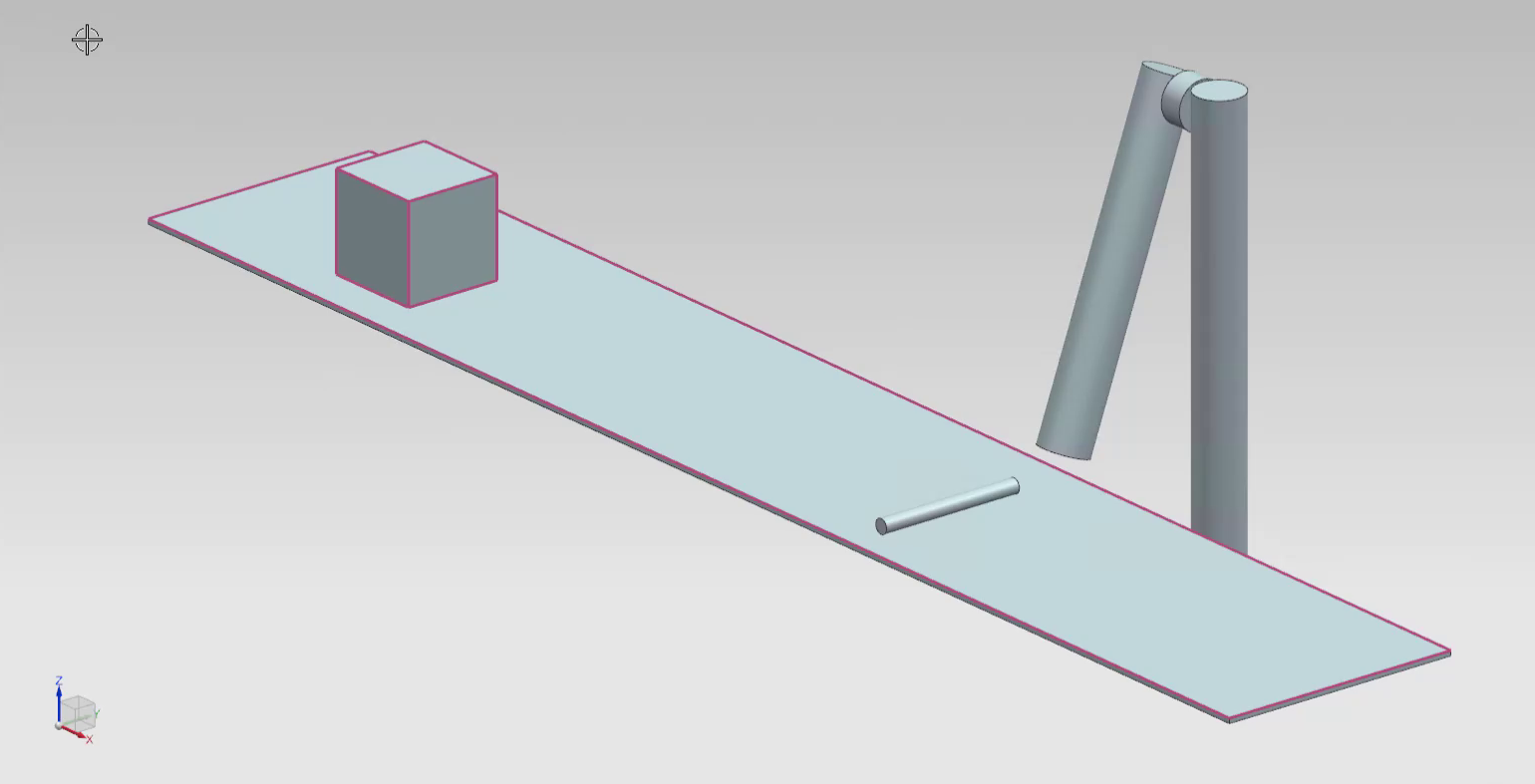

For this task, the correct assembly can be found in simple_robotic_arm. Download all the parts from the simple_robotic_arm file and open ASSEMBLY_simple_robotic_arm in Siemens NX.

Preparation

- Siemens NX MCD

Assignment

In this exercise, a running simulation of a simple robotic arm mechanism will be created. The CAD files are available. In Siemens NX MCD, different physical properties will be assigned to parts in order to reflect the function of the simple station.

When you first start NX, you may get an error saying there are no licenses available. Click “OK” and navigate to File -> Utilities -> Select Bundles. In the window that opens, select and add both available bundles then click OK. This solves the error.

Box and Conveyor Band

In the first steps, rigid and collision bodies will be assigned to parts that will interact with each other.

Todo

- Assign a rigid body to the box and call it

Box. - Assign a collision body to the box and call it

Box. Hint: to choose the entire box volume, right-click on the box and select "Choose from list". Then select the entire box from the list. - Assign a collision body to the upper surface of the transporter band and call it

Transport_band. - Assign a transport surface to the upper surface of the transporter band and call it

Transport_band. Specify the correct direction vector and set the parallel velocity to 100 mm/s. - Run the simulation and check if the box is transported on the transport band.

Simple Robotic Arm

Todo

- Assign a rigid body to the robotic arm and call it

Robot_arm. - Assign a collision body to the robotic arm and call it

Robot_arm. - Assign a hinge joint to the robotic arm and call it

Robot_arm_HingeJoint. Specify the direction vector and the anchor point in a way that it rotates around the robotic joint. - Assign a position control to the hinge joint object. Test different Destination and Speed settings.

- Finally, set the destination to 0 and the speed to 500 °/s.

Collision Sensor

Todo

- Assign a collision sensor to the small cylinder on the transport band and give it a suitable name.

Conditions - Using Operations as if-Statements

Todo

- Create an operation in the Sequence Editor. Choose the position control object as the Select Object choice. Make a check next to position and give a value of 70. Select the collision sensor object as the condition object and specify that

triggered == true. Name the operationArm_out. - Create a second operation. Choose the position control object as the Select Object choice. Make a check next to position and give a value of 0. Select the collision sensor object as the condition object and specify that

triggered == false. Name the operationArm_in.

Run the simulation and check if it achieves the desired behavior.